Step by Step: Futureglass

During December Design Insider will explore the production processes behind our members’ most unique and innovative designs.

Last week we saw how Boss Design created Trinetic, an innovative office chair that encourages a correct ergonomic posture through dynamic technologies. Today we visit Future Glass to explore the processes they use to create their versatile bespoke glass pedestal table.

The trend for glass reception tables enables Futureglass to maximise their expertise in bespoke glass designs, giving their customers unrivalled choice. Furuteglass can customise their tables with a variety of bespoke colours, finishes and materials.

1. We work with the client to produce a design we can integrate into the furniture. We cut a mask and remove areas to be sandblasted.

2. The stencil is then applied to the toughened glass table top.

3. The release paper is carefully removed from the mask and the stencils integrity is inspected before the high pressure sandblasting.

4. We then satin polish the stainless steel fitting to get the surface finish and appearance we need before bonding it to the glass.

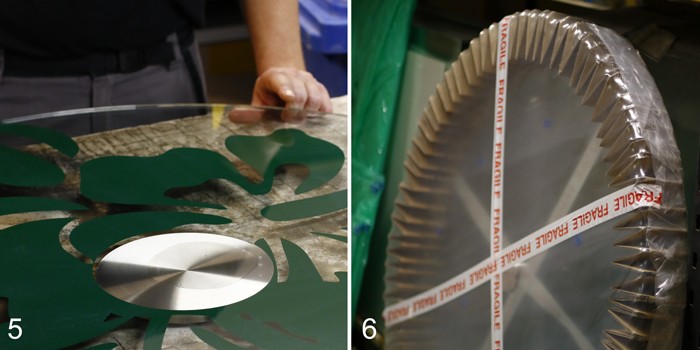

5. Once the boss has been polished and thoroughly cleaned, it is then bonded to the underside of the glass top.

6. Our 100% recyclable Design registered packaging is then used for reliably shipping the product to the customer.

Let us know in the comments below or on Twitter at @DesignInsider1