Valuing Waste to Help Reduce Carbon

Following on from our recent article highlighting material-led projects that harness the power of diverting waste streams, we continue to shine a spotlight on those creating value in transforming disposed items into useful surfaces.

By now, anyone with an interest in surfaces and interiors will know of the world’s first timber terrazzo, Foresso. Launched in 2016, the unique solid surface diverts scrap wood from waste streams and has been consistently specified on commercial and residential projects ever since. We’ve previously reported about the pioneering work co-founders Jake Solomon and Conor Taylor have been doing with the material, and now the team is evolving their offering with an exciting new initiative. Low Carbon Industrial (LCI) is the next logical step in the duo’s mission to radically reduce the carbon footprint of architectural materials, and as ever, performance, aesthetics, practicality, and sustainability are at the heart of the brand’s ethos.

As co-founder Conor Taylor explains:

“With Foresso, we learned just how much the design community values tactility, storytelling, and sustainability when it’s done right – it’s all woven into the fabric of the brand, rather than trying to shoehorn environmental credentials into an existing manufacturing setup. LCI is our next step: building the materials we wish existed, with a clear carbon agenda and a belief that the future of interiors is circular. Together, we’ve built something different. Not only are we doing things differently, but our customers are doing so too. They’re helping to shape a future where lower CO2 is the norm. We’re proving that beauty, performance, and environmental intelligence can come as standard. ”

With the launch of LCI comes the debut of a new material, Elenite. This premium solid surface is produced from post-industrial, natural waste materials, including walnut shell, walnut dust, and bamboo fibre. Created in partnership with Taiwan-based manufacturing specialists, Meganite, Elenite cuts embedded carbon by 29%, and future batches are already in development to increase that reduction to 50%. The range comes in four earthy shades, which are made using natural pigments, while no silica, formaldehyde, or water is used during manufacturing. What’s more, any waste generated is fed back into the process, creating an optimum circular production process.

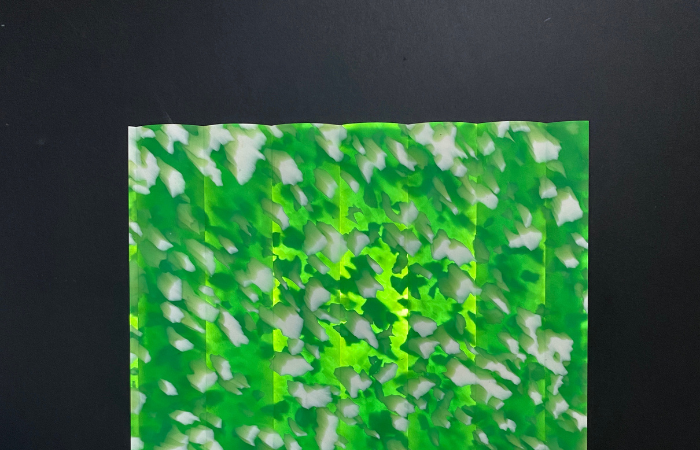

Reducing carbon through manufacturing is also a key objective of the Chinese material manufacturer, DECO DECO. Their glass resin panels use surplus material as a base, transforming scrap material that would otherwise go to waste, while allowing for ongoing recycling. Like Elenite, their surfaces are formaldehyde-free, and come wth a European Standard certification. What’s more, their unique translucency allows for an interplay with light, with speckles of opaque colour creating dappled effects, while natural elements such as leaves and petals suspended in transparent glass allow for particle privacy.

Diverting waste materials from landfill, and instead recognising and applying a value to them instead is at the heart of the work Renée Materials do. Recognising that an alternative system could be put in place, the team looks to match companies’ offcuts, surplus stock, and leftover waste with those who need materials for creative projects. The product range includes a vast mix of hard and soft materials, in an array of sizes, from yarn to tile, leather to wood, and packaging to paint.

Founded by Frieda Bischoff and Vassi Deij while still students at the University of Arts London in 2023, the studio is still in its early days, yet the impact of the UK’s first hybrid marketplace for reclaimed creative material can already be quantifiably measured. Prior to exhibiting during the London Design Festival, where visitors were invited to rummage in what felt like a vintage store of materials, Renée had saved nearly 20 tonnes of waste from landfill. And as the duo are keen to point out, by redirecting materials in this way, they are actually cutting down CO2 emissions twice – once by reducing waste and again by replacing the need for new material production. For businesses, such as Bill Amberg Studio, this means reducing waste, creating an additional profit, and even saving on disposal, while for consumers, there is up to a 50% saving in buying materials – along with the knowledge that you’re helping the planet in some small way.

The same can be said for those buying furniture from Opus Magnum’s ReCrafting initiative, such as Legal & General, which supplied ten boardroom tables, originally made in 2007, for repurposing. From them, the team redesigned a new circular table, with hinged material matched flaps in the centre and a round pedestal base. The original tops were cut into a new shape by CNC according to their grain pattern, and then artfully joined together.

Additional off-cuts have also been used to produce the base, thus reducing the need for virgin steel, as well as minimising scrap. The resulting 2000mm diameter table looks like an entirely new piece, and a striking centre piece for any boardroom.

The same can be said of a series of Walnut flip-top tables supplied by Baird. Travelling only a few miles across London, the Opus Magnum team took the time and care to remove old, worn veneers and replace them with new, durable finishes. Working closely with Renuables Ltd, they have calculated that ReCrafted tops create 28.5 kilograms of Carbon Dioxide emissions, which is a vast reduction on the 174.4 required for the equivalent in new materials. Thus, underlining the impact, and indeed value, of such conscientious decisions.