Innovation Strategies from BCFA members

Design Insider went out to BCFA members asking them to share some of their experiences of a innovative strategy, here is what they said:

Can you share a specific innovation strategy you’ve recently encountered?

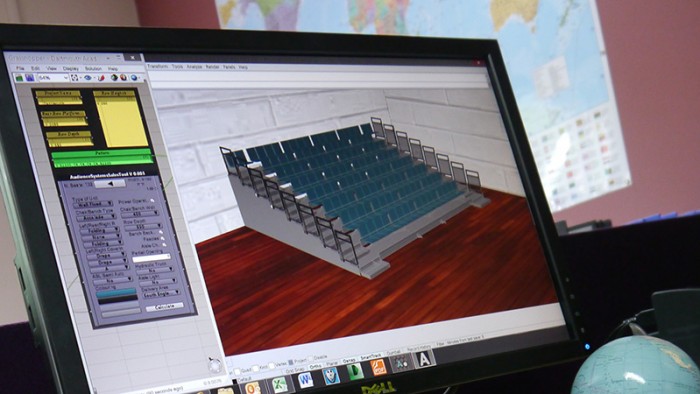

Audience Systems

Developing tools to assist our customers has been a key focus of late. We recently launched our BIM objects, and modelling retractable seating has been a challenge. However we focussed on keeping file sizes small while keeping them user-friendly and customisable. We have had great feedback. But BIM objects have their limitations and we have also developed 3DV, our own in house design tool. In it we can model a seating system for a venue pretty much instantly, produce a 3D visualisation and price. This has proved invaluable to our clients particularly in the early phases of specification, has helped to keep our quoting process fast and lean.

Hansgrohe

Our job is to make products that function and stay contemporary for 25 years. Hence, we try to go beyond short-lived trends and styles when thinking about how to innovate something durable. The better product is the one that you have to decipher during the design process: we reduce complexity, remove everything that is not absolutely necessary, go to the essence of its function. Our strategy also consists of challenging ourselves: if we take a step back while working on a project and doubt where we are, we start again.

Gresham

Newcastle University embraced technology in their Marjorie Robinson Library Rooms – a library without books – and asked us to collaborate with them. They wanted to actively promote a `Bring Your Own Device’ philosophy. A varied study environment was created using colour palettes and furniture including seating clusters, private booths and office-like pods; all with integral technology. The end result exceeds both client and students’ requirements by seamlessly blending modern café-culture with business professionalism.

Innovative ergonomics are at the fore of our new task chair which will be unveiled at Clerkenwell Design Week – come along and see us to find out more!

Newmor

The Newmor strategy is to invest in both manufacturing and design to fully realise the potential that investment in new printing technology brings. It is our graphic design capability, combined with our expertise in manufacturing which allows us to offer a unique custom design service. We can digitally manipulate artwork to create special print effects, at the same time we can create unique textures and select from a range of substrates to meet individual client specifications.

Johnson Tiles

Our Artile service demonstrates how there really are no boundaries when it comes to tile design. Our recent collaboration with artist Nina Beier saw us reproducing natural textures such as dry cracked mud, concrete and marble onto large format tiles. Artile perfectly replicates any design – such as a drawing, sketch or even original artwork – onto tile. Its ability to accurately reproduce every tiny, intricate detail with no loss compared to the original has also seen us replicating Aboriginal art onto tile for the first time.

GX Glass

We’re looking at a number of business innovations, which we hope will result in cost savings that we can pass onto our customers. These include a self-quoting system, a table-based CAD drawing system and introducing a VOIP system to ensure everyone in the business is contactable from a central point.

Morgan

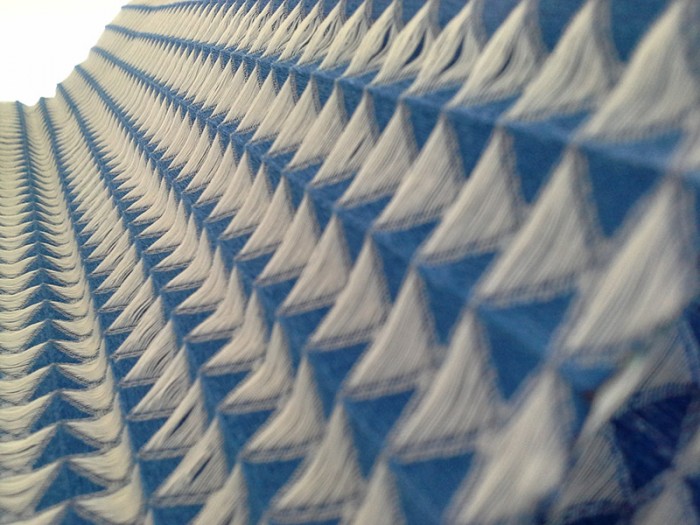

The Morgan design team has been collaborating with architect and designer Mehran Gharleghi to develop a series of products using the latest 3D printing technology. Through this project, we played with the concept of combining the traditional techniques of timber craftsmanship with the emerging materials and processes of 3D printing. This not only offers a new construction method, but explores an exciting hybrid design language.

Chad Lighting

One example of exploiting an existing means of manufacture would be in the recent development of a light (Panino) using a manufacturing process predominantly used to produce skirting boards. Visiting a company and endeavouring to understand the limitations and possibilities of a process, in order to utilise that process to produce a product not normally associated with that process requires innovative thought and experimentation.

Trevira

We believe that close customer cooperation along the value chain can enhance new product development. This implies that raw material supplier, producer and distributers of the final product act as partners on the market. This is especially true for a product like Trevira CS, where the flame retardant properties constitute the function in the final textile. We also think that joint projects with Universities and Research Institutes can also generate new impulses and ideas which lead to new products and processes.

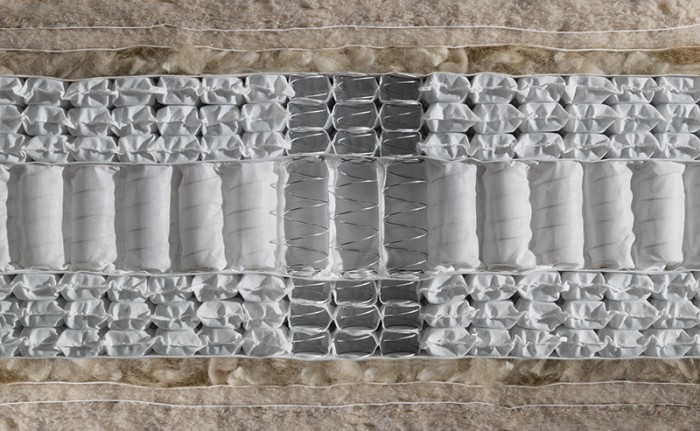

Harrison Spinks

With our own machinery, built in-house, we’re able to draw our own wire, which in turn allows us to produce more than 20 million springs per week. This innovative technology has led to the company manufacturing mattresses with a spring count of more than 40,000 – a figure which far outweighs our competitors.

As well as providing beds with an industry leading spring count, we have utilised our spring technology to create a pioneering upholstery range and a cot bed mattress collection featuring the world’s smallest pocket springs.

Chelsom

Working massively in the marine industry we have had to innovate considerably in many ways but especially when it comes to the way in which glass and crystals are suspended on cruise ship chandeliers which are often large in terms of scale, intricate and heavy because of the sheer weight of the crystal. The ships are obviously subject to rough weather and engine vibration so we have had to completely rethink how glass and crystal are fixed to metal sculptures. Chains, loops and rings have been replaced by threaded rods and glass parts drilled to take such rods so they are fixed solid. Specially engineered casings are used to bond glass parts and special coil spring sections fixed to the ends of crystal drops to prevent vibration.

Style Library Contract

Our most recent innovation strategy was the launch of Anthology Fabrics. Our target was to create a sophisticated range of contract suitable fabrics at an excellent price point. Our Group Contracts Director, Carolyn Mitchell, is thrilled to have this selection of fabrics within the company’s portfolio: ‘The brief was to create a library of essential luxury, taking contract fabrics to a new level in the market whilst still being mindful of value for money. Anthology fabrics have been designed and sourced specifically for trade to give interior designers free rein to express their flair and creativity.’