Jim Biddulph & Anthony Millington in Conversation

2019 is proving to be a busy year for Amron Architectural. Experts in the supply of metal mesh here in the UK; they’ve already added the colourful metal chain curtain range Kriskadecor to their portfolio and have also recently welcomed Anthony Millington to the team in a new Business Development role.

He joins a company with a decade of experience in supplying specialist metal mesh to the architectural and interior design industry worldwide; whose parent company, Wire Belt, has over 30 years knowledge and experience of producing precision metal belts for conveyor systems.

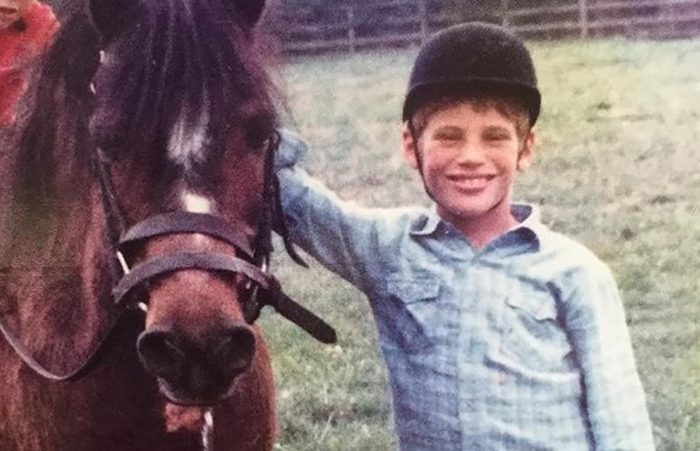

Anthony himself comes with a wealth of knowledge and experience of metal mesh having worked with it for over 15 years, although it wasn’t always the path he looked set to take. Indeed, he’s not your average metal mesh expert; his roots take him back to dairy pastures and his favourite past times generally see him on a bike or a board. I spoke to him to find out more about his unique journey and how he takes an educational approach to his material of choice when working with clients.

JB: So I know that you’re background growing up nearly sent you off in a very different direction to working with metal mesh, can you tell me more about it?

AM: I grew up in Leicester and the family ran two businesses: a dairy farm and a builders merchant that had outlets across the Midlands. I spent most of my holidays working on the farm but did get drawn into the building side of the business over time. However, I went to University to study Agriculture, although that didn’t last long as the college was in Devon and I spent more time surfing than learning! To add to that, the CJD outbreak then hit the dairy industry and I agreed with my family that maybe the dairy Industry wasn’t quite what I should be doing, so went into the family firm, which was subsequently sold out to a larger high street merchants.

JB: I guess going from a building merchant to working in the supply of metal isn’t a huge step, but how did it all progress in reality?

AM: I met my previous colleague Simon Cadisch back in 2002; he was a friend of my older brother and in the metal mesh business for industrial applications. He joked that they were getting strange calls from architects about using mesh on buildings but couldn’t help them, as they really didn’t understand what was wanted. It was then mentioned that putting the two companies together, one with the history of working in the building Industry and the other with great knowledge of metals. This was my cue to step in as it immediately appealed to the way I could see the aesthetics of architecture going. We set Cadisch MDA up and started to develop a range of metals and finishes that we could take to the market. When we started I did everything from marketing to sales, logistics and everything in between, all from a small office in Finchley.

JB: With such in depth experience of the industry, would you say that you have developed a distinct approach to supplying metal mesh?

AM: I have always felt that the architectural industry has not benefitted from companies simply trying to sell product or shoe horn a product into a project where it really doesn’t fit. I would rather advise and guide the client to get them exactly what they want or even advise another companies product if I felt ours was not right, rather than offer the wrong thing which will leave clients ultimately disappointed. I want to be able to walk past a project that we have worked on and be proud and not think that something else would have looked better.

JB: So how do you get to that glorious end point, do you have any tricks up your sleeve?

AM: I generally aim to be as close to the concept stage of a project as possible, usually at or just after first visual stage. That way the client’s expectations can be properly managed and we can offer or develop the products correctly. This helps reduce issues later on in the process, which is also important with costing as it allows all parties to assess whether what is being offered is actually affordable for the project.

After 17 years in the industry, my A&D client base is substantial but my history with façade contractors is something that I would like to focus on in my new role at Amron. At the moment, the company looks more towards the interior fit out market than the external envelope, but the material is highly suited to outdoor environments, so that’s something that we can work on. I am also actively helping develop a marketing plan that can be worked to over the next 12 months and that we’re all very excited about that!

JB: Well, in terms of looking ahead, are there any trends in the metal industry that our readers might look out for?

AM: Currently the trends are definitely towards taking standard products and making them more bespoke and personalised to the client or project. Originally we would take a standard product, cut them to size and polish, powder coat or anodise to a standard colour. Now products are formed, shaped and finished to create one off installs. Powder coats now can emulate so many different patina and textures, which means we can bring certain things like “rusty” metal inside without all the issues normally associated with it. This ageing of metal is one of the most popular trends we have seen in recent years; it seems that there’s a real focus on provenance and aged history at the moment.

JB: You strike me as someone who enjoys a challenge and to really push yourself, no matter what you’re doing. Do you think this will continue to be your approach to your new role?

AM: As a 19 year old boy I always envisaged that I would be dairy farming somewhere in the countryside and would never have imagined that I would be working with specialist metals for architecture and becoming someone that people know to come to for anything metal, but I wouldn’t change the outcome. I had to work hard and strive to get to this position. With the move to Amron I am extremely excited to push things on again working with a great team with the same energy and excitement that I have for the products, so it really is onwards and upwards!