Open Cell create Covid-19 testing facilities from shipping containers

There are few organisations that can boast to having laboratory teams working on DNA sequencing, synthetic biology, bioelectronics and bioplastics amongst its ranks, but Open Cell in London’s White City certainly can. Tucked away amongst the normal hustle and bustle of Shepherds Bush Market is a mini village comprising of 70 shipping containers, which have been converted into fully equipped laboratories aimed at early stage biotech start-ups. Innovative material developers including mycelium specialists Biohm and Chip[s]board who we recently interviewed about their bioplastic made from potato waste have called it home, as well as nanorobotics company Nanovery and Olombria, who encourage flies to be better pollinators.

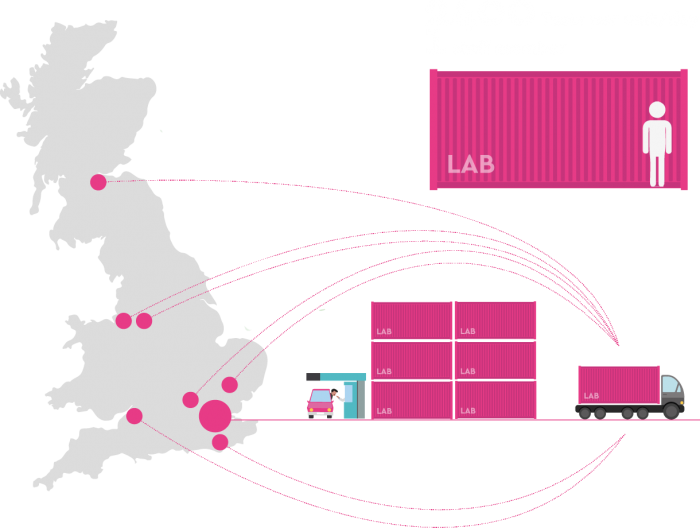

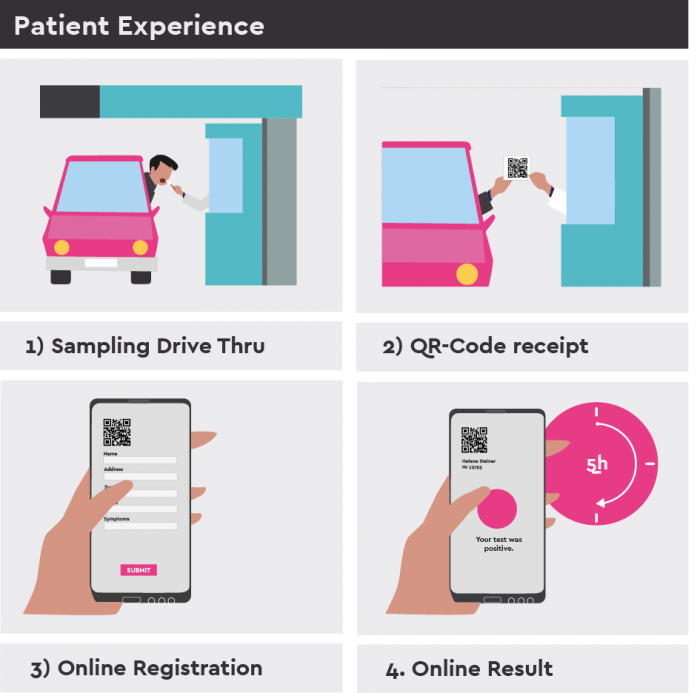

However, as an early response to the now international Covid-19 pandemic, the team at Open Cell took the initiative to design containers that operate as specialist testing laboratories. The aim of the emergency labs is clear – to augment existing NHS facilities and reduce the burden on hospitals by outsourcing testing away from vulnerable people. Open Cell founder Helene Steiner has pointed out that, “we have to fight this virus with a long-term strategy. We have to get in our mindsets that this is not a sprint, it is a marathon.” Whilst the approach of the PHE and NHS is to centralise testing, OpenCell’s approach is to decentralise testing, making it more widely available for frontline key workers as well as the general public.

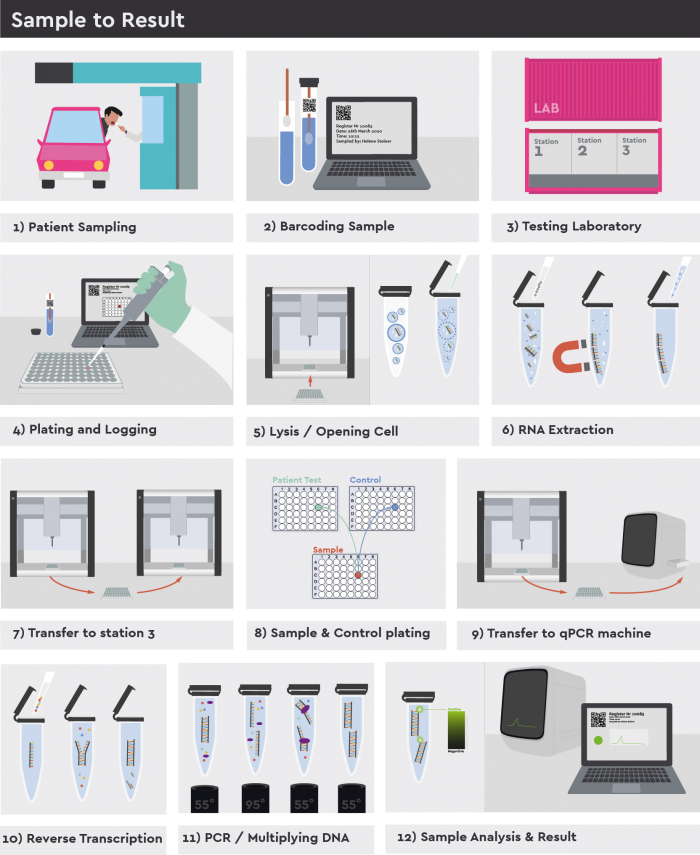

As we have seen, a lack of infrastructure, equipment, test-kits and available staff approved by PHE and the NHS has led to the government falling well short of the 10,000 daily tests they initially aimed to carry out. The Open Cell labs are equipped with liquid handling robots and along with a member of staff, can deliver 2,400 tests a day. The process itself is a complex one but involves extracting viral RNA (ribonuleic acid) from a sample, such as a nasopharyngeal swab, and amplifying it to a measurable level so that it is possible to see whether a patient is infected with COVID-19. What differentiates OpenCell’s labs is the automated RNA extraction protocol using a magnetic-bead based method rather than column-based methods, which insulates OpenCell from some of the global demand on RNA extraction kits.

Another main benefit of OpenCell’s project is that it is open-source. Over 200 volunteers world-wide are currently contributing towards the challenges involved in developing testing capacity. The next steps in the plan are to create 39 container labs in order to increase testing capacity to 80k tests per day for the UK, and as the labs are constructed from shipping containers, they have the potential be made in any country and moved to any necessary location.

As we are all experiencing, there is much uncertainty, concern and hardship as a result of the virus but as Marcus Walker of Open Cell points out, “easy, frequent and abundant testing may be our best route to normality before a vaccine is ready.”

Whilst we continue to observe social distancing and hope that it helps to flatten the curve of the virus whilst work is carried out on a vaccination, we can be particularly thankful that in times of unprecedented strife, tenacious and pioneering innovation does come to the fore.