Sustainable Design with Rock Galpin & Erin Johnson

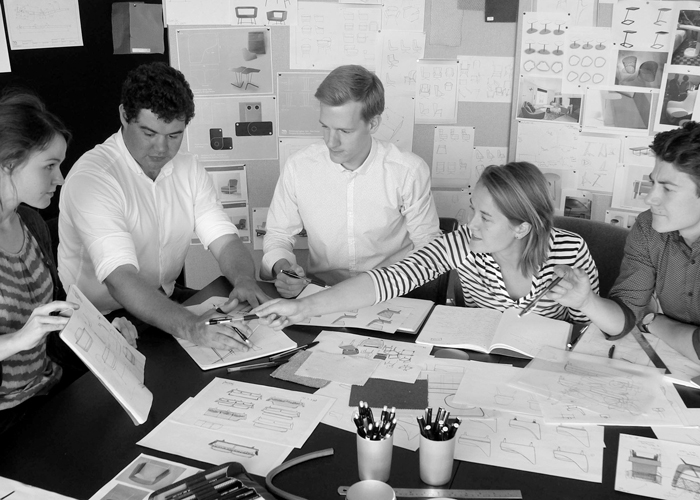

Erin Johnson is Design Manager, and a member of the Senior Management Team, at British contract furniture designer and manufacturer Morgan, where she has worked since 2008. As such, she is responsible for the design process and new product development, ensuring every detail flows smoothly throughout and into production as a fully launched collection. she also manages the daily running of the design team.

Erin and her team have had the privilege of working closely with designer Rock Galpin on Morgan’s new Lugano collection. We took the opportunity to speak with Erin (EJ) about sustainable design at Morgan and to discuss inspiration and sustainability with Rock (RG).

Why is sustainability at the core of design and manufacturing at Morgan?

EJ: If we don’t take responsibility for our impact on the environment, then we don’t have a right to create. So, sustainability must be at the core of everything we do: from the materials we source and how we only consume what is vitally necessary to the way in which we heat our own factory with our own timber waste and provide a new lease of life to our product through our re-upholstery service.

Throughout the design process, we consider the sustainability of our product through material type, quantity and source. We work closely with both our supply chain and Production team to get the best result for all interested parties.

Crucially, our products can be broken down at the end of their life into their constituent parts and the material can be recycled.

Could you explain your ‘make once, make well’ approach?

EJ: This stems from our belief in ‘Right First Time’, a Lean manufacturing principle which strives to minimise waste. This principle involves a culture of continuous improvement, so that we are always aiming for a way to better ourselves, our processes and our thinking. It is a firm part of our organisation’s values and can be applied throughout our business, not just in our manufacturing facility. Along with eliminating waste through defects, Lean encourages us to minimise resource lost through other means, including overprocessing, overproduction and waiting.

How have you integrated this approach into your design process?

EJ: One example is a streamlined process we’ve developed, linking Design, Prototyping and Production when launching a new product. Clear communication and transparency are vital to ensure that all Production team members get to ‘experience’ a product prior to a collection launch. By running test orders of product through the factory, we are able to assess all improvement opportunities prior to our external launches. This allows us greater control and more opportunities for improvement.

How did you address sustainability through the design of Lugano?

RG: I was once asked 15 years ago, ‘what was the most sustainable car brand’. Their surprising answer was, ‘Porsche’. The simple fact that the most sustainable product fundamentally is of course one that lasts an extraordinarily long time, and can then be reproduced. Porsche design cars to last, on every level, from the build, of course, but also with a powerful timeless appeal.

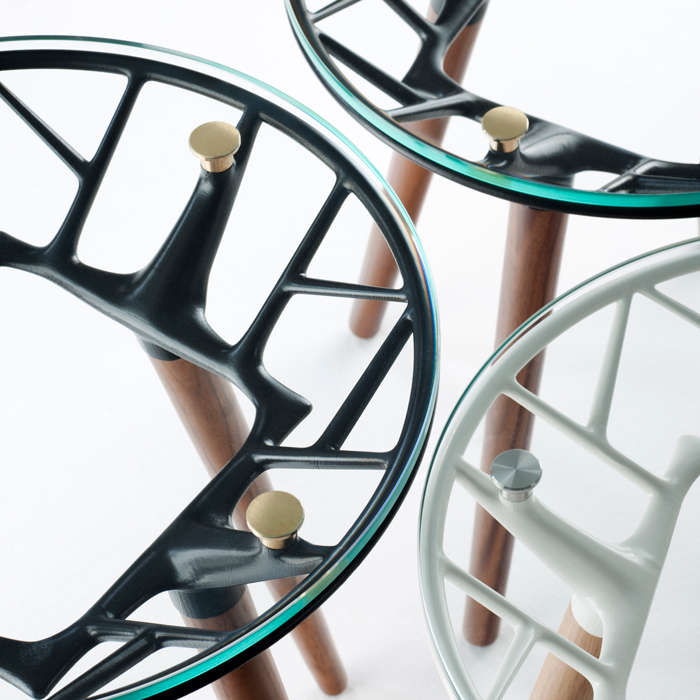

The Lugano collection uses a similar approach, deriving from ‘make once, make well’, an approach which resonates profoundly with both parties and expresses the objective for excellence in design combined with high quality production with the aim of timeless use and appeal.

There has also been a growing trend towards interior designers looking to create further differentiation in their personal product design style, and also clients looking for interior designs that are increasingly unique. So the idea of a collection that combines long lasting use and style with flexibility in options and could be updated and refreshed, we believe, represents a strong, sustainable proposition.

Are there ways in which you plan to further address sustainability through the design process?

EJ: Our next aim is to further focus upon being more innovative with our material usage and material types. We’re excited to explore material development and research in greater depth. Not only will it open up more opportunities for increasing our sustainability credentials, it will give specifiers and designers greater creative freedom.

We recently added two plastic top options to our Goodwood tables, both 100% recycled and recyclable, while our Modena and Rakino collections offer the choice of a terrazzo tabletop, made of recycled chip materials. Every new option we can provide increases design potential and possibility.

What was your inspiration behind the design of Lugano?

RG: The Lugano Collection was simply inspired by the idea of ‘to nurture and be nurtured’, a direction originating from Morgan’s designer brief, which placed special importance on a new level of comfort.

For me comfort is about many things, from familiarity, like a soft pebble that fits your hand perfectly or the warm hug from a close friend; confidence inspiring, reliable and providing an inner calm and strength. The notion of a hug was largely where the typology originated from, with the extended paddle legs cradling or ‘nurturing’ the upper chair and the person seated.

Contact Rock Galpin

Contact Morgan through BCFA Product Finder

The BCFA Product Finder is a unique search engine created especially for interior designers to source contract furnishing companies. Utilising this platform will support your findings for upcoming projects, with over 200 members profiles showcasing the latest product launches, new materials available, industry news, and design trends.

Comments