WASTE NOT – a more sustainable future for plastic furniture

Plastic’s unique properties make it an unparalleled material for mass furniture production. Utilising it responsibly in a circular economy is vital for a sustainable future.

Amongst the rallying cries for greater environmental responsibility, the anti-plastic campaign has gained momentum resulting in the demonisation of this ubiquitous material. Like so many issues, there is no one simple answer. The reality is that plastic does have significant merits and the greatest enemies are single use applications, irresponsible disposal, and waste.

Plastics are everywhere. It is hard to think of any other material that has so quickly, and so profoundly changed humanity. Almost all the plastic ever to exist has been produced in the past century or so, the vast majority of which still exists today.

Its many desirable properties and versatility have seen its usage proliferate to a point where it has become virtually impossible to live without it. Its ubiquity and near-indestructibility is also quickly becoming problematic with single use applications, irresponsible disposal and raw materials extraction.

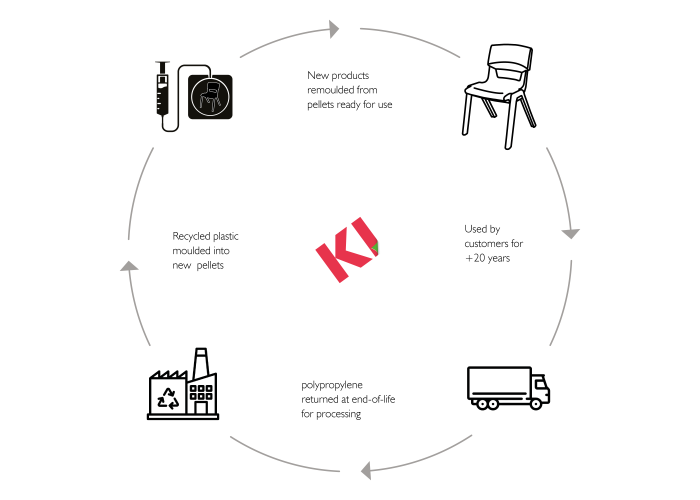

As with any material, there are numerous positive and negative impacts throughout its life cycle. For applications where plastic’s unique merits make it a material of choice, we are all responsible to mitigate, or even eliminate where possible, the negative effects of its use. Long product lifespans and creating a closed loop circular economy can be very effective ways to eliminate contributions to landfill, or worse, into the ocean.

The fact is that plastic has a vital role as a lightweight, durable, low energy-intensity material, that if recycled properly can have a sustainable future. Recycling polypropylene, for example, actually takes considerably less energy than creating new material and plastic is infinitely recyclable.

Plastic is an ideal material for furniture. It is strong and easy to clean, making it uniquely suited to environments requiring improved hygiene, helping to reduce the transmission of disease. Schools, healthcare environments and many other public spaces all feature plastic-based furniture. In addition, the reduced mass and volume also impacts on transportation costs resulting in lower fuel consumption and associated emissions during the production and distribution process.

KI’s seating products & innovations in plastics technology

KI offers a wide range of seating solutions manufactured from plastic. The iconic Postura+ chair, for example, has been used by millions of students all over the world since 1996. Its ergonomic design makes it comfortable, lightweight, easy to lift, manoeuvre and stack. Its features, production process and affordability have all been thanks to the unique properties of its materiality. Made from high impact resistant copolymer polypropylene, Postura’s gas injected legs increase strength and reduce weight. Its material makes it easy to create a range of attractive, vibrant colours. They are strong, light, stain resistant, antistatic, easy to clean and vandal resistant. These features, combined with a 20-year warranty, ensure a long, functional lifecycle. At the end of this cycle, the chairs are 100% recyclable.

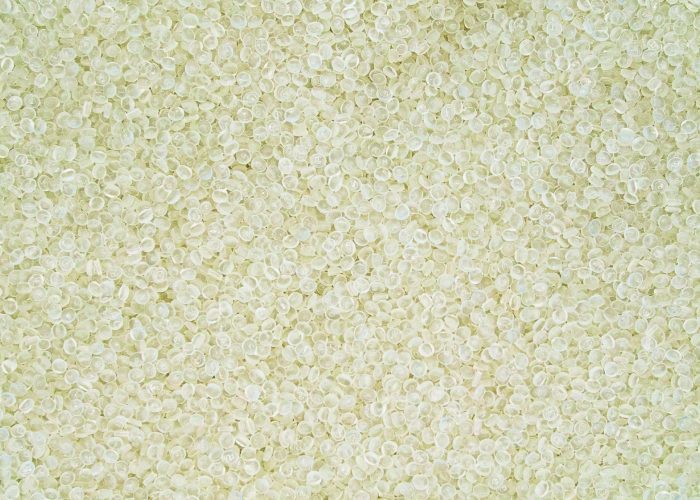

To further enhance the sustainability of the production of these chairs, the facility in which they are manufactured is part of a network of supply chain partners with global leadership in plastics technology and recycling. Its dedicated ERIS (Environmental Returnable and Industrial Solutions) division has already transformed many industrial sectors through the development of 100% reusable, recyclable or compostable plastic-based materials. The UK operation has developed a unique additive which means that the properties of recycled plastic are similar to that of virgin polymers. In addition, plastics that would not otherwise be compatible can be processed and recycled allowing the recovery of a higher proportion of plastic waste compared to standard recycling.

From 01 November 2022, all newly manufactured Postura+ one-piece chairs will be made of 30% recycled material and KI is committed to incremental improvements in the near term, subject to maintaining high quality and testing performance. This increased usage of recycled content is part of a movement towards a closed loop lifecycle for plastics that will gradually reduce the volume of virgin plastics by focusing on recycling.

Collection and reverse logistics will form part of this plastics loop. KI is working with recycling partners that provide facilities that can transform plastic chairs into plastic pellets, which will in turn be the feedstock for newly manufactured products. This is particularly straightforward with the Postura+ one-piece chair as it is 100% polypropylene and does not require any disassembly.

We all have a responsibility to make considered choices to protect the planet for future generations. The investment in durable products, like Postura+, which are easy to recycle is a positive for the environment. Ongoing investments in reuse and recycling innovations will ensure that we value waste as an asset, rather than relying on finite petroleum extraction to produce virgin materials.

Contact KI Group through Product Finder.

Product Finder is a unique search engine created especially for interior designers to source contract furnishing companies. Utilising this platform will support your findings for upcoming projects, with over 200 members profiles showcasing the latest product launches, new materials available, industry news and design trends.