Millbrook Beds introduces NemoFlex™ – the future of sustainable sleep

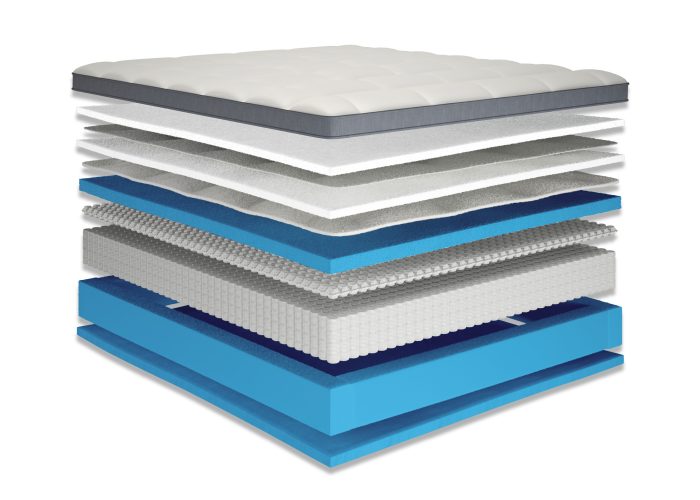

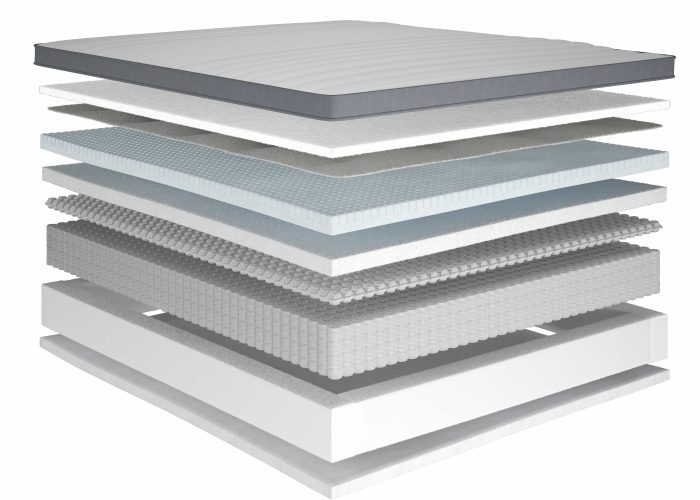

Millbrook Beds announces the future of sustainable sleep with the invention of NemoFlex™ Technology – a trade-marked and unique encapsulated core spring system designed with the end-of-life of a mattress in mind.

[Find Millbrook Beds on the BCFA Product Finder]

Drawing upon 75 years of knowledge and experience in making mattresses, Millbrook Beds has created NemoFlex™ in response to growing concerns over the alarming statistics around plastic pollution and the challenges of mattress disposal.

A mattress with a NemoFlex™ ecapsulated core spring system at its heart can be de-constructed in under five minutes and achieve a 100% recycling capability. Easy to remove, it significantly reduces the time and cost of re-processing, making recovery and re-purposing of valuable materials more efficient, and helping reduce the number of waste mattresses going to landfill each year.

Recycled polyester in the NemoFlex™ core is made using a minimum of 200 plastic bottles and gives the mattress borders extra strength without the need for traditional hand side stitching, these unique, exclusive borders have been two years in development.

Introduced to the range via the new Chittenden & Eastman and the Eclipse Laguna collections, NemoFlex™ core technology will also be incorporated into the wider range of Millbrook Beds mattresses over time.

From September 2021, for every mattress sold featuring NemoFlex™ technology Millbrook Beds Co will donate to the Woodland Trust, through its newly created Dream Trees initiative, which has been conceived to support the creation, protection and restoration of UK Woodland.

Ross Thurston, Operations Director of Millbrook Beds Co comments, “As a bed manufacturer our focus for many years has been on sourcing sustainable, natural fabrics and fillings, with sustainability driving both our corporate responsibility and customer scrutiny. But with 167,000 tonnes of mattresses in the UK going into landfill every year, we felt our responsibility must also lie in the issues surrounding mattress disposal.

NemoFlex™ technology was conceived from the start with end-of-life in mind. Consideration for how a mattress is recycled has become a key factor in our manufacturing, without any compromise to comfort or quality.

We’ve taken 75 years of experience and knowledge in bed making to create something new and exciting to take sleep into a more sustainable future. It’s a very exciting time for Millbrook Bed Co as NemoFlex™ takes us a step closer to carbon neutral manufacturing.”

Contact Millbrook Beds through BCFA Product Finder.

The BCFA Product Finder is a unique search engine created especially for interior designers to source contract furnishing companies. Utilising this platform will support your findings for upcoming projects, with over 200 members profiles showcasing the latest product launches, new materials available, industry news and design trends.