Rio 2: Sustainable Production

Morgan, contract furniture designer and manufacturer, has combined skills and expertise with architect Mehran Gharleghi of studio INTEGRATE to launch Rio 2, a new collection of tables for the contract market that include 3D printed components. Here we introduce this collection and the sustainable nature of it’s design.

The first of its kind within the sector to include this cutting edge technology with a commercially viable price point, the sophisticated and luxurious collection is not to be missed.

The first Rio collection was launched in 2016, combining the skills and expertise of the Morgan team with Mehran Gharleghi’s knowledge of new technologies to explore the relationship between the craft of yesterday and the craft of tomorrow.

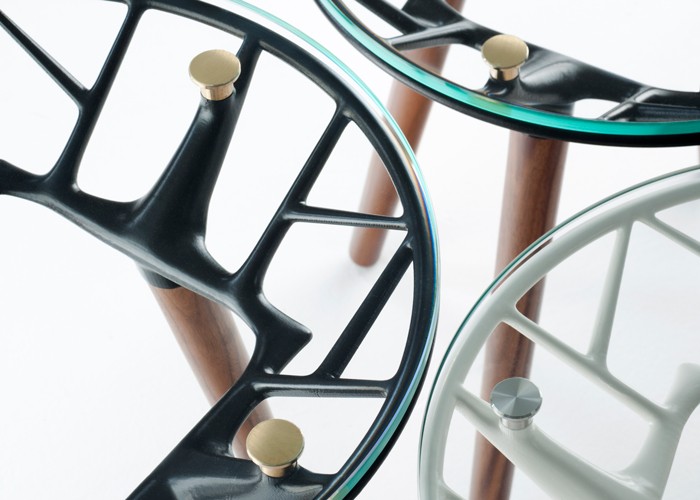

The second generation sees two new table designs. With this version, a greater understanding of the technology provided the designers with increased creative scope, resulting in a more geometric and regular aesthetic, as opposed to the organic feel of the first generation. The use of materials was also reduced and refined, adding further options to the entirety of the collection. On the edge of design and technology, the tables are an iconic piece at an affordable price.

The collection uses a polyamide 3D printed component as the main structure with which to attach a glass or timber top and timber turned legs. The polyamide used for Rio 2 has excellent mechanical properties as well great recyclability potential. For example, recycled polyamide can be used in textile industries. It is also well suited to form carbon-fiber-reinforced, graphene-nanoplatelets-reinforced or metal-porous-polymer composite structures.

The production technique for Rio is an additive process and therefore not only offers design freedom, but also a sustainable manufacturing solution, reducing waste significantly. Unlike subtractive manufacturing, additive manufacturing (3D printing) only utilises the material necessary to produce an artefact. It adds the material layer by layer until the item is complete. Excess powder is then recycled and used for subsequent production.

As 3D printing becomes increasingly accessible, some manufacturers are choosing to run their production in house, which reduces transportation and improves logistics.

Both Mehran and Katerina Zachariades, Morgan’s design director, approach design in different ways; Katerina sketches and draws to scale with a pen, whilst Mehran designs digitally through modelling. Initially this resulted in a series of miniature 3D printed resin prototypes from Mehran and then full-scale models from Morgan. These two processes allowed the team to review the design both aesthetically and in terms of scale and proportions giving an immediate sense of reality.

Through the design process, Morgan and Mehran managed to increase the factor of strength three fold. This was done by introducing geometric differentiation in various parts of the table according to the structural analysis conducted by Morgan Studio. Digital analyses were informed by previous Furniture Industry Research Association (FIRA) testing and guidelines. By establishing an iterative feedback loop between design and analysis, the team perfectly balanced the cost, strength and aesthetic of the collection.

Contact Morgan through the BCFA Product Finder.