Responding creatively during the pandemic

As the Covid-19 pandemic persists across the globe the vast majority of industries remain at a stand still or at best, a slow trundle, and with this comes much debate and prediction surrounding the future state of individual nations and indeed the world economy. It’s safe to say the majority of predictions look bleak, which is perhaps a driver for a number of message shifts here in the UK and even major protests across the water as governments and individuals attempt to integrate an economic restart into their future planning.

Whilst it seems frivolous to discuss which industry may have been the worst affected, not least because we don’t know what the end of this actually looks like, it is safe to say that the design world has been hit. Here in the UK, construction has remained partially active throughout the process of lockdown, but many companies have still had to furlough a majority of staff in order to accommodate reductions in workload as well as the practical changes bought about by new social distancing guidelines. Elsewhere, whilst some have been able to work from home – a necessity for many freelancers deemed ineligible for financial support – there has been a sharp downturn in work for the vast majority within the creative sector. The cancelling of both Clerkenwell Design Week and the London Design Festival are significant additions to the now long and ever-growing list of cancelled design fairs; events that many creatives normally rely upon.

But, proving that creative endeavour continues even in the most unsettling of times, many designers and artists have adapted their normal practice with attempts to help make a difference. For instance, whilst many parents have been forced to home school their children – a new and fairly alien experience for the majority – creatives up and down the country, including the likes of Grayson Perry, have offered online art classes via various video conferencing platforms (a fairly novel tool to many at the beginning of lockdown too.)

Designers and makers are also offering their support to the NHS and associated healthcare sectors by shifting their manufacturing processes to create the equipment most needed, and in many cases lacking, throughout the UK. Whilst big engineering firms such as Airbus and Rolls-Royce have led the charge in creating ventilators others have taken the news of shortages in personal protective equipment into their own hands.

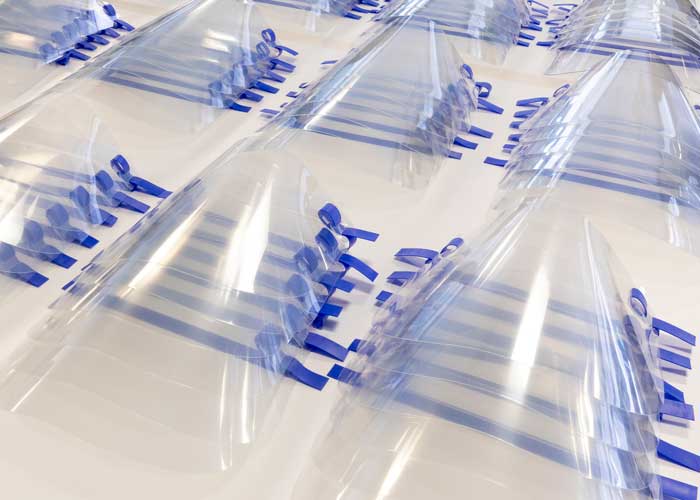

With many projects on hold Foster + Partners have turned their attention to creating general-purpose face visors with fast manufacturing processes in mind. The prototype visor, designed by a team of industrial designers, modelmakers, architects and analysts, is made from three components: a visor made from 0.5mm optically clear PETG, an interlocking soft PP headband, and a surgical silicone rubber head strap that ties the two together. The easy to clean component are all cut on the practice’s digital flatbed cutter and what’s more, they’re allowing the designs to be open sourced:

“We are sharing the design templates and material specifications as an open-source design asset. This is to encourage both designers and in particular large-scale manufacturers to investigate the potential of digital and laser cutting machines as an alternative to 3D printing technology.”

On a more localised scale, maker and keen recycler Bill Bremner spotted a fruitful piece of plastic waste, the humble beer keg, and has been transforming them into face visors. Having turned a store of clear kegs he’d previously collected during his time as a volunteer at beer festivals, he is now taking them off the hands of breweries. One 20-litre keg can provide eight face shields and Bill has already provided hundreds of them free of charge to doctors surgeries, care homes, hospices and to district nurses.

Open source project Precious Plastic are joining the dots between large-scale manufacturer and independent makers through the adaptation of their plastic injection machines, which utilise recycled plastic and are said to be far faster than 3-D printers. Groups and individuals from the Precious Plastic community around the globe, including Gran Canaria and Germany, are busy providing PPE in the form of visors and respirator masks that can be made quickly and without the use of predominantly virgin materials.

Whilst there are a number of reasons available for not wearing facial protection; lack of availability, saving it for the sake of those who need it more, and some even still questioning the need for it at all; there are others who may argue that comfort and if brutally honest, style, are behind their lack of mask or visor. American brand Joe Doucet X Partners have acknowledged this as a challenge that needs to be tackled by design. Taking the view that there may well be a need for long-term solutions, they have designed a face-protecting shield with integrated sunglass lenses and arms with the aim of “making them more practical and feel less alien and intrusive on the wearer than a typical face shield.” As well as coming in unisex styles, the shields are also sprayed with UV protective and anti-fogging coatings. The polycarbonate body can once again be easily cleaned and reused and they even hope to go one step further by teaming up with Parley to develop face shields made form recycled ocean plastic.

Which brings us neatly round to an important concern that many have raised during the lockdown; increased plastic waste. Daniel Webb of Everyday Plastic summaries these concerns:

“We’ll definitely see a rise in PPE litter over the coming weeks, months, even years. Most of the facemasks are made of a soft plastic that isn’t recyclable in many countries. But the rise in PPE waste is essentially a ‘known known’, so, as was the case already, recycling and waste processors should be looking for opportunities to make use of these resources.”

As such, initiatives that re-use or recycle plastic in the creation of PPE are certainly an ideal scenario, but Daniel also raises another pertinent point and perhaps one that we should all consider when it comes to designing, making or buying PPE:

“It’s also important not to confuse the single-use plastic crisis with the rise in PPE. Doing so provides petrochemical companies with the chance to portray themselves as heroes in being able to provide solutions.”

Image Credit for Fosters + Partners: Aaron Hargreaves