2018: A Busy Year for Harrison Spinks!

It’s been a busy and successful year for Leeds-based bed maker Harrison Spinks!

In February the fifth-generation family business strengthened its commitment to British manufacturing by investing £1.8million in a new wire drawing facility on British Steel’s site in Scunthorpe.

The new lines will draw the ultra-fine wire used to manufacture Harrison Spinks’ world-leading pocket springs, using steel rod from British Steel.

The investment created 22 new jobs in total and will produce approximately 400 tonnes of fine wire for its springs each week. The company already employs more than 600 people.

In April it received two prestigious Queen’s Awards for Enterprise, bringing the total number won by the company to four. It was one of only eight organisations that received more than one accolade in the 2018 awards.

It was awarded a Queen’s Award for Innovation and one for International Trade. It has previously won Queen’s Awards for Innovation and Sustainable Development.

Simon Spinks, Managing Director of Harrison Spinks said: ‘Since the company was established in 1840, we have always strived to innovate and go about our business in a slightly different way, whether that be creating new ways to manufacture springs or cultivating our farm so we can grow our own natural fillings. We’re delighted to be recognised by the most prestigious enterprise awards in the UK.’

Further awards followed in July as the company’s spring division, Spinks Springs, won The Furniture Makers’ Company’s third annual Export Award.

The company developed a worldwide export business through its innovative Posturfil and HD micro-springs that act as a comfort layer and replace foam and other filling materials in products such as beds, footwear, upholstery and office furniture.

The judges were impressed how, through the development of an international strategy and continuing to increase investment in the people within each new market, Spinks Springs’ export business has grown by 500% since 2015, with export sales in 2017/18 reaching £4.89m and now accounting for 17% of its sales.

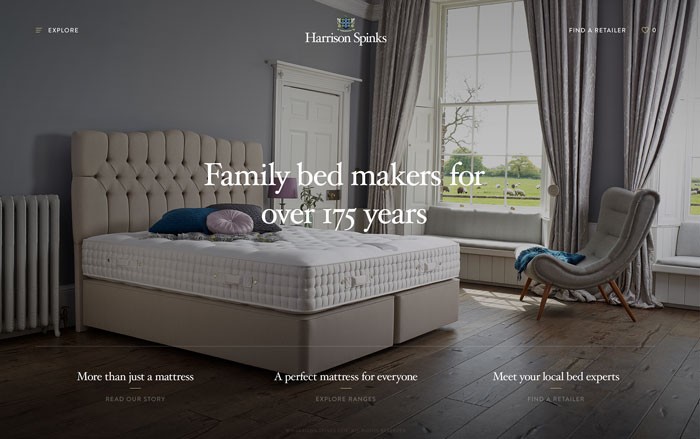

In October, and as part of a £1.5 million brand overhaul, Harrison Spinks launched a new consumer-facing website designed to create a ‘best in class’ experience to help drive brand awareness and support commercial growth.

For the first time, the website unifies Harrison Spinks’ bed brands – Harrison, Somnus, and Spink & Edgar – all on one site.

On Friday (7 December) Harrison Spinks formally opens its brand new £2.5 million Innovation Centre at its headquarters and manufacturing site in Leeds.

The Innovation Centre houses the company’s development team, management, sales and marketing teams and also a state-of-the-art showroom.

The development took two years to complete and creates a focal point at the company’s sprawling site in Leeds. The development connects the factory, warehouse, testing facilities and offices and provides communal spaces for employees.

Simon Spinks added: ‘Innovation is at the heart of our business so allowing our development and innovation teams to be under the same roof as the marketing and operations side of the business means we can work collaboratively more easily. The development of the Innovation Centre followed hours of consultation with our staff on how we could improve our working environment. The staff feedback about the new offices and communal spaces has been really positive and the whole team has been behind the change. We don’t just want to reinvent the bed, we want to reinvent the bed factory and much, much more!’

Earlier this year for #WoolWeek Harrison Spinks told Design Insider about their commitment to wool. For fifth generation family bed-maker, wool is prized as a natural filling for its luxury mattresses. So much so thatthey bought their own wholly-owned farm in North Yorkshire in 2009, where prize Texel, Mule, Suffolk, Wensleydale and Zwartbles sheep are reared by hand to produce pure-grade Yorkshire wool for its beds. Read our article here.

Contact Harrison Spinks